Definition of Process Control Block

The Process Control Block is a data structure that stores essential information about a running process. It acts as a repository of the process’s execution context, allowing the operating system to manage and control each process effectively. The PCB is created when a new process is initialized and remains associated with that process throughout its lifetime.

Purpose of Process Control Block

The primary purpose of the PCB is to provide a centralized and organized repository for storing critical information about a process. It acts as an interface between the process and the operating system, enabling the OS to track and manage processes efficiently. The PCB holds vital data needed for scheduling, resource allocation, and process synchronization, helping the operating system juggle multiple tasks concurrently.

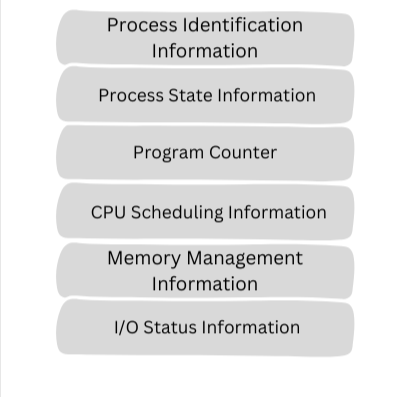

Components of Process Control Block

Process Identification Information

This component includes details that uniquely identify a process, such as its process ID (PID), parent process ID, user ID, and group ID. It helps the operating system distinguish between different processes and manage them accordingly.

Process State Information

The process state information indicates the current state of the process, whether it is running, waiting for input/output, or suspended. It helps the operating system keep track of which processes are active and ready to execute.

Program Counter

The program counter (PC) stores the address of the next instruction to be executed in the process. It enables the operating system to switch between processes and resume them from where they left off.

CPU Scheduling Information

This component contains details about the process’s priority, scheduling algorithm, and execution history. It helps the operating system prioritize processes and allocate CPU time based on predefined rules.

Memory Management Information

The memory management information holds data about the memory requirements of the process, including the base and limit registers. It assists the operating system in allocating and deallocating memory resources to processes.

I/O Status Information

The I/O status information keeps track of the process’s ongoing input/output operations, such as devices being used and their status. It helps the operating system manage and control I/O operations efficiently.

Functionality and Importance of Process Control Block

Managing Multiple Processes

The PCB plays a crucial role in managing multiple processes simultaneously. It allows the operating system to keep track of each process’s state, priority, and resource requirements, ensuring fair and efficient execution.

Context Switching

Context switching, the process of saving and restoring the state of a process, relies on the PCB. When the operating system switches from one process to another, it saves the current process’s state in its PCB and loads the following process’s state from its PCB. This allows for seamless transitions between processes.

Resource Allocation and Deallocation

The PCB assists in resource allocation and deallocation. By storing information about a process’s memory requirements, I/O operations, and other resource needs, the operating system can efficiently assign and manage resources to ensure optimal utilization.

Process Synchronization

For processes that require synchronization, the PCB helps facilitate communication and coordination. The operating system can ensure proper synchronization between processes by storing synchronization-related information, such as shared resource usage or inter-process communication channels.

Exploring the Structure of a Process Control Block

Anatomy of a Process Control Block

The PCB is typically composed of different fields or attributes that store specific information about the process. These fields collectively form the structure of the PCB and allow for easy access and retrieval of process-related data.

Detailed Description of PCB Fields

The specific fields within a PCB may vary depending on the operating system. However, standard fields include process ID, process state, program counter, CPU scheduling information, memory management information, and I/O status information. Each field has a designated purpose and contributes to the efficient management of processes.

Understanding the Role of Process Control Block in Process Management

When it comes to managing processes in an operating system, the Process Control Block (PCB) plays a vital role. The PCB is like the brain behind the scenes, keeping track of important information and ensuring everything runs smoothly. Let us dive into the various aspects of the PCB and how it contributes to process management.

Process Creation and Termination

The PCB is involved in the creation and termination of processes. When a new process is created, the operating system allocates a PCB. This PCB contains essential details about the process, such as its process ID, priority, state, and memory allocation. It is like a personal identity card for each process, allowing the operating system to keep tabs on what is happening.

On the other hand, when a process terminates, the PCB associated with it is deallocated, freeing up resources. The PCB ensures that all the allocated resources are correctly released, and that the terminated process does not leave any clutter behind.

Process Suspension and Resumption

Sometimes, processes need to be suspended temporarily. This could happen due to various reasons, like resource unavailability or user intervention. In such cases, the PCB comes into play again. It saves the process’s current state, including the values of its registers and program counter, allowing the process to be resumed later from where it left off.

When a suspended process is ready to be resumed, the PCB provides all the necessary information to the operating system, giving it the ability to restore the process’s state and continue execution seamlessly.

Tracking Process Information

One of the primary tasks of the PCB is to track and store vital information about each process. This includes details like the process’s current state, its priority, the resources it is using, and its relationship with other processes. The PCB acts as a central repository for all this information, making it easily accessible to the operating system.

The PCB also keeps track of the process’s scheduling information, allowing the operating system to make informed decisions when it comes to process scheduling. It is like a cheat sheet that helps the operating system keep everything organized and running efficiently.

Impact of PCB on Scheduling Decisions

The content of the PCB can directly impact the scheduling decisions made by the operating system. For example, if a process has a high priority level or is in a critical state, the scheduling algorithm may prioritize it over other processes. The PCB’s information helps the algorithm understand which processes should be given more attention or resources.

By using the PCB as a reference, the scheduling algorithm can optimize the utilization of system resources and enhance overall system performance.

Conclusion and Future Developments in Process Control Block

In summary, the PCB is the backbone of process management in an operating system. It handles the creation, termination, suspension, and resumption of processes while also keeping track of vital process information. The PCB plays a crucial role in process scheduling, guiding scheduling algorithms to make informed decisions.

As technology continues to evolve, we can expect future developments in the PCB’s functionality. New features may be added to enhance process management, improve resource allocation, and optimize system performance. The PCB will continue to be a key component in the efficient execution of processes within an operating system. In conclusion, the Process Control Block (PCB) is a fundamental component of operating systems that allows for efficient process management.

The PCB enables the operating system to allocate resources, schedule processes, and ensure synchronization by storing crucial process information. Understanding the structure and functionality of the PCB is essential for developers and system administrators alike. As technology evolves, the PCB will likely undergo further advancements and optimizations to enhance process management. By harnessing the power of the PCB, operating systems can continue to improve performance, efficiency, and overall system stability.